Parallel Continuum Robots

Research at the intersection of parallel robots and continuum robots

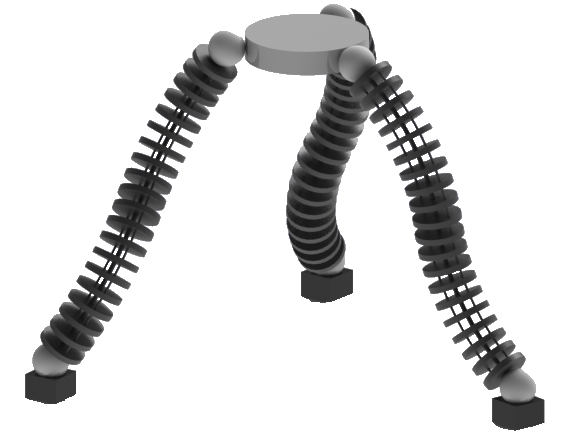

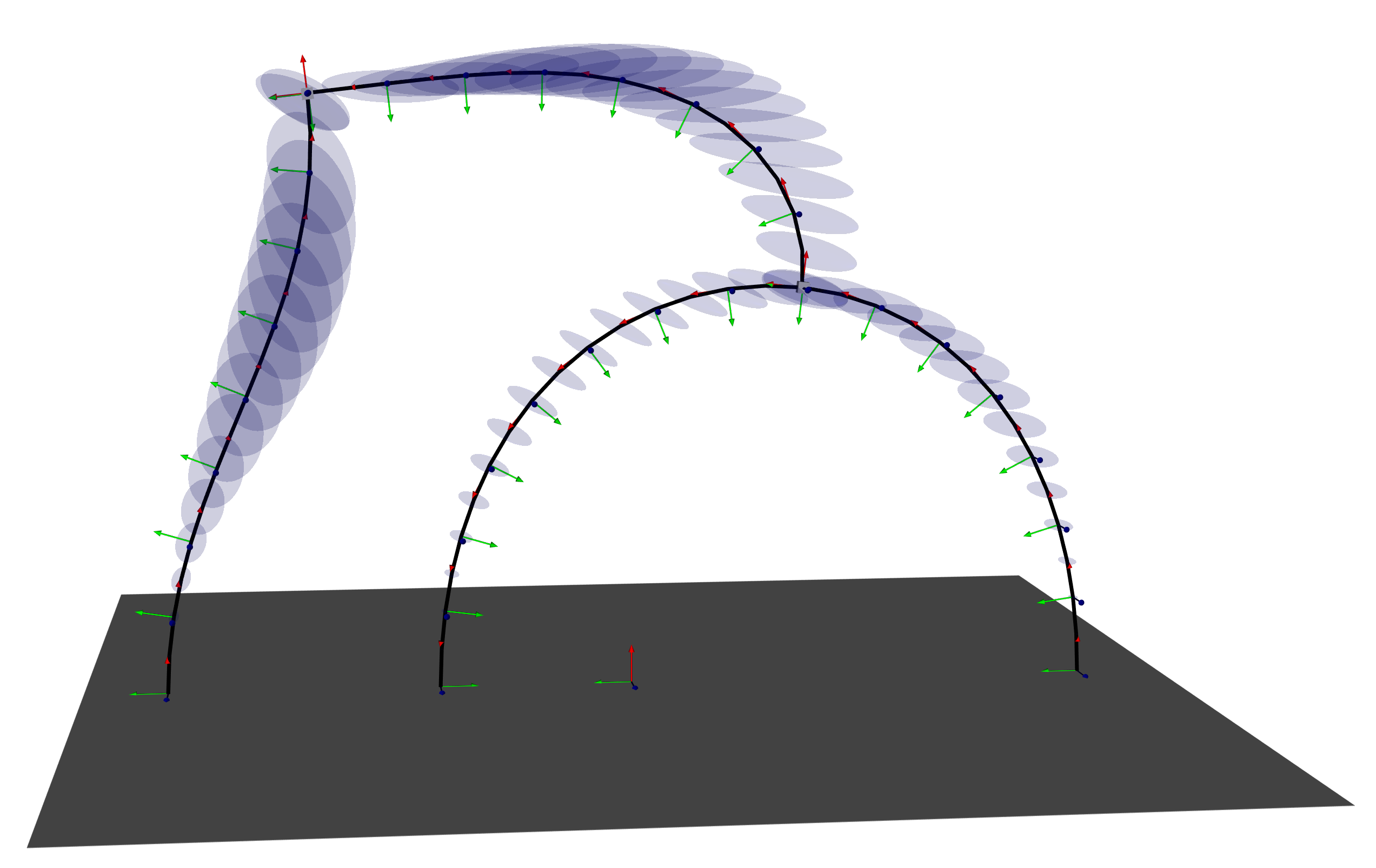

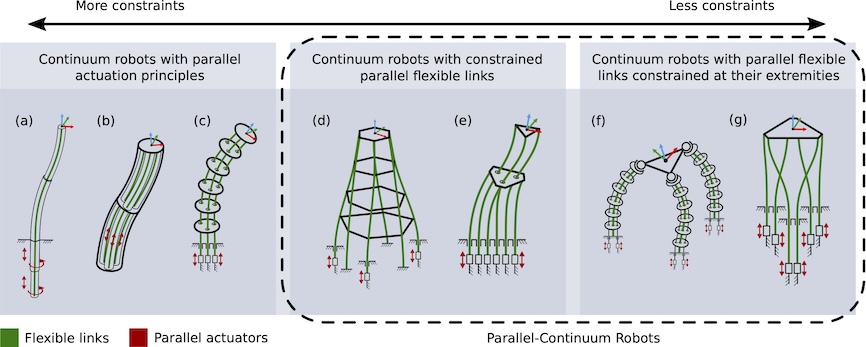

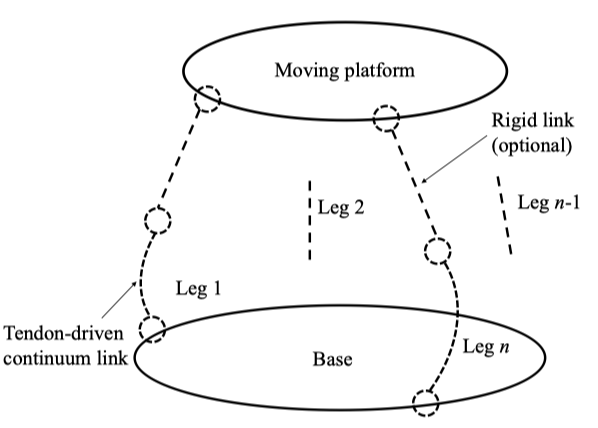

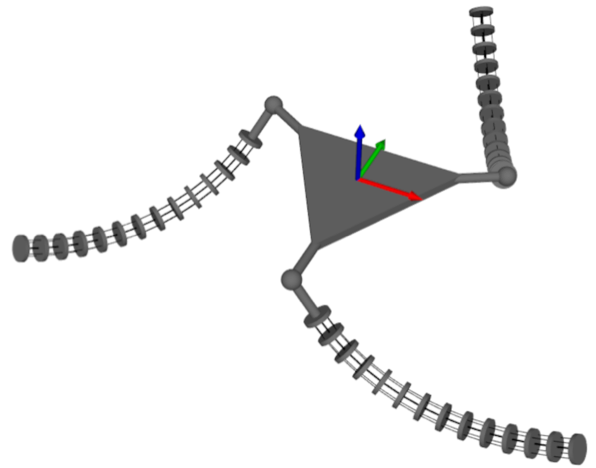

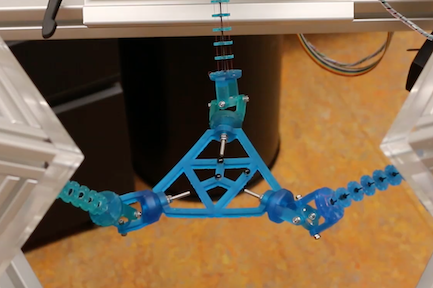

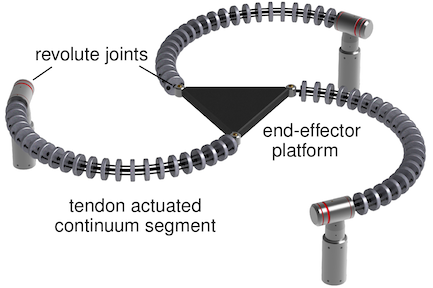

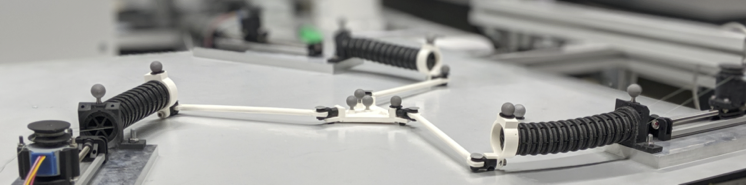

In this project, we are researching tendon driven continuum robots (TDCR) that are working collaborative in parallel coupled structures. The resulting structures can be classified as parallel continuum robots and consist of multiple individual continuous kinematic chains, that are actuated in bending utilizing tendons routed along their backbones. The parallel setup aims to overcome the drawbacks of tendon driven continuum robots such as a relatively low load capacities and position accuracies, while maintaining their inherent compliance and dexterity.

We want to answer three key questions!

- How to model the proposed TDPCR structures accurately and efficiently?

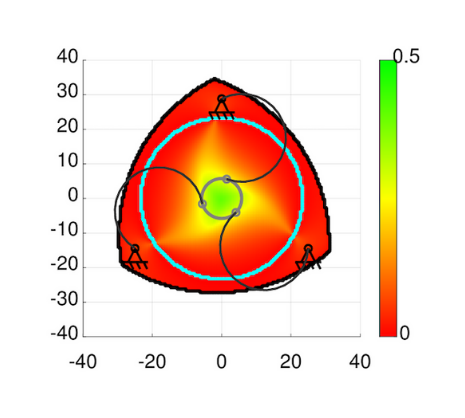

- How to kinematically design TDPCR, ensuring good manipulability and stiffness?

- How to control TDPCR and utilize their kinematic properties with respect to their proposed use case?/li>

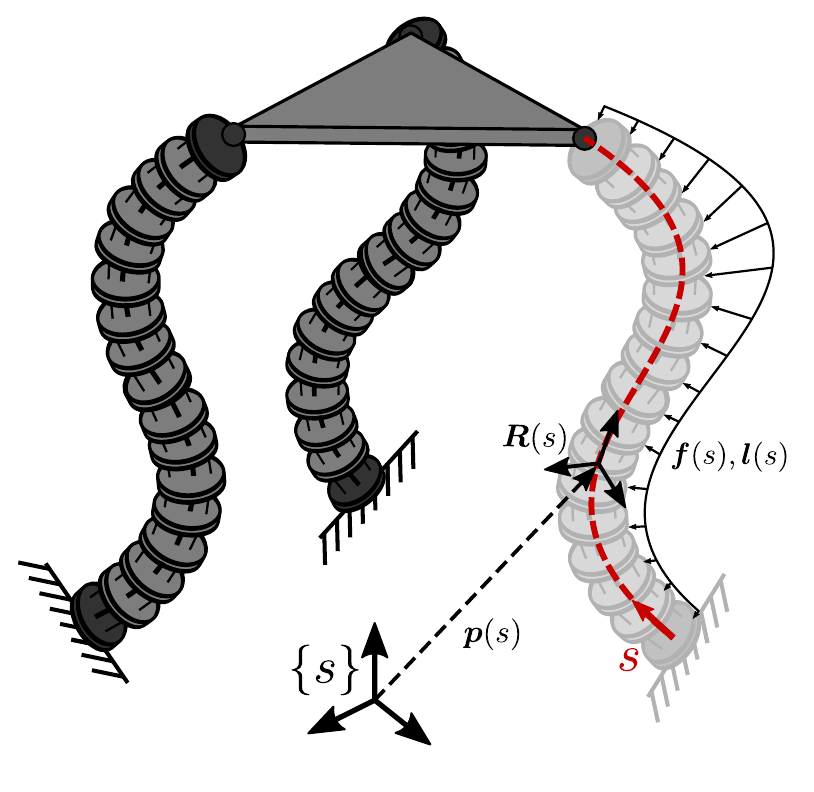

The studied structures could allow for scenarios in which multiple tendon driven continuum robots are individually inserted into a highly constrained workspace through different insertion paths, before coupling into a parallel manipulator to increase the stiffness and accuracy of the overall system. We envision that such a robotic system could for instance be used for inspections and repair tasks of aircraft engines, where the continuum robots enter through borescope holes and couple into a parallel robot to inspect and repair the turbine's blades.

Our Areas of Research

Prototype Design

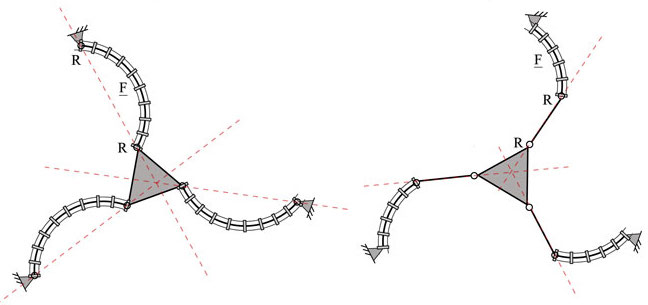

For the design of TDPCR, we are investigating different design parameters for the individual tendon driven continuum robots as well as various possibilities to couple them into a parallel manipulator. This creates a broad design space, resulting in a large variety of possible TDPCR structures with different kinematic properties.

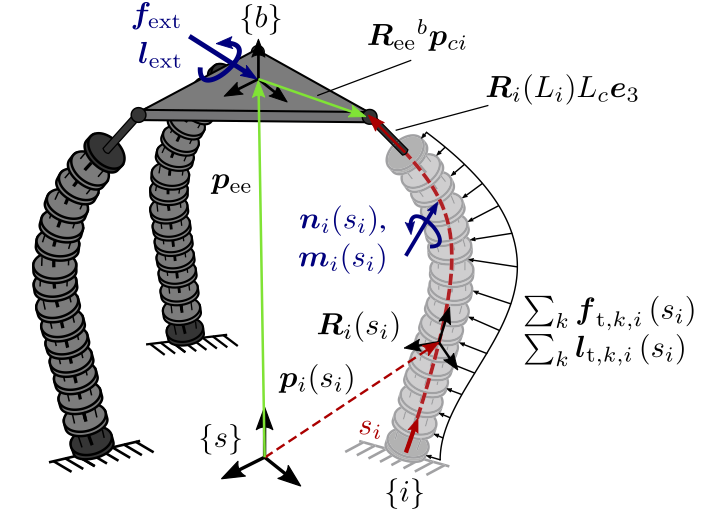

Modelling

Leveraging the elasticity theory of slender rods, we are deriving kinetostatic modeling approaches for TDPCR, allowing us to solve their forward, inverse and differential problems, which relate the robot shape to its actuation values and external loading. Based on derived modeling approaches, we are investigating and evaluating the kinematic features of TDPCR throughout simulations, gaining valuable insights about their workspaces, manipulability and stiffness properties and singularity occurences.

Control

Lastly, we are focusing on approaches to effectively coordinate and control the TDPCR motions in task space. We are particularly interested in efficiently resolving possible kinematic redundancies, resulting from the high number of degrees of freedom in configuration space.

Publications

IEEE Transactions on Robotics, 40:3252-3270, 2024.

Frontiers in Robotics and AI, 9:1082185, 2023.

Journal of Mechanisms and Robotics, 15(4), 041003 (10 pages), 2023.

Workshop on New Frontiers of Parallel Robotics. IEEE International Conference on Robotics and Automation, 2022.

IEEE Robotics and Automation Letters, 6 (2), pp. 1272 - 1279, 2021.

IEEE Robotics & Automation Letter, 5 (4), pp. 5811 - 5818, 2020.